Electroless UBM Formation Service

Summary

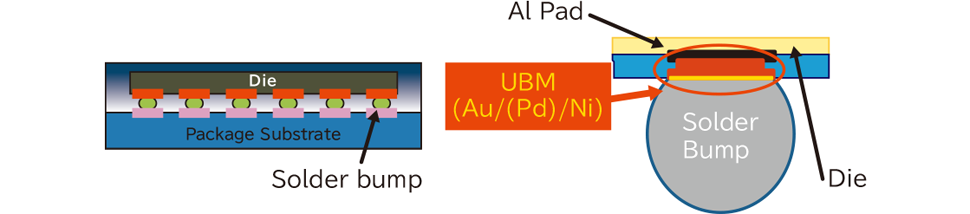

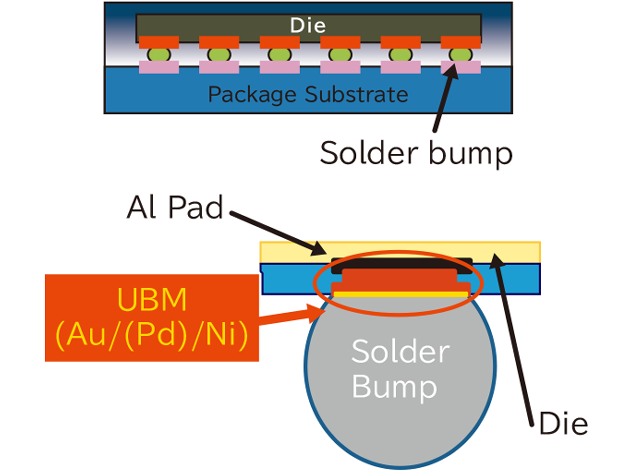

Flip chip bonding is increasingly taking over conventional wire bonding for bonding of microchips, as semiconductor packaging technology advances toward smaller sizes and higher density. Under Bump Metallurgy (UBM) formation to bond metal pads to solder is considered to be essential in flip chip bonding. Our UBM process makes use of electroless plating technology, offering advantages such as lower cost, faster delivery, and smaller size, as well as consideration for the environment.

Application Examples

- What is UBM?

- Under Bump Metallurgy (UBM) is the process of plating metal layer to enhance the reliability of joint by soldering bumps or bonding-wire on electrode pads of semiconductor.

Benefits for Customers

- JX process meets the need of customers

- ・JX Plating process can perform the uniformity stably and good appearance on:

(i) Large Electrode Pads being more than 1cm on Discrete

(ii) Small Electrode Pads being less than 10µm on Flip Chip - ・Plating on the thinner wafers / the wafers requiring backside protection

- ・Support for wafer sizes of up to 12 inches

- ・Plating on both sides of a wafer at the same time

- ・JX Plating process can perform the uniformity stably and good appearance on:

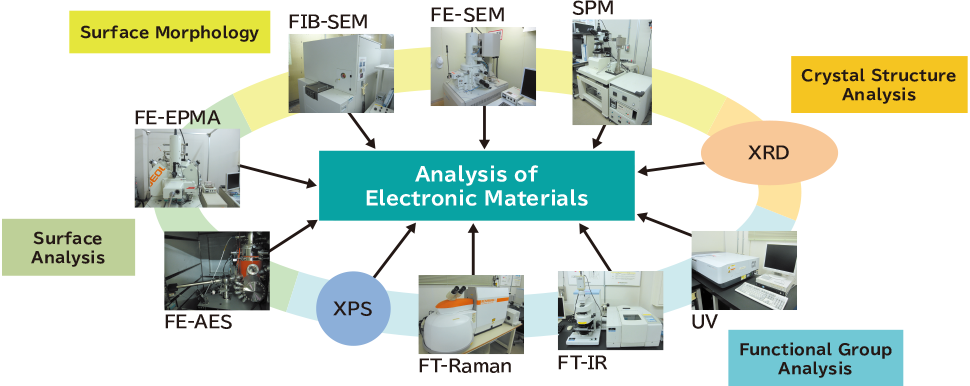

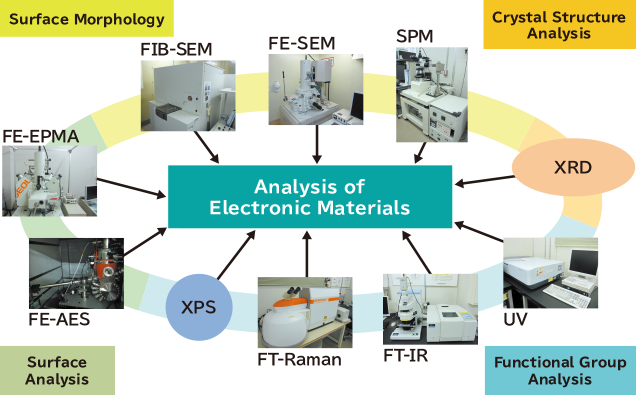

- Abundant facilities make it possible to analyze the plated film quickly

Standard Specification

| Wafer | Si , GaAs, SiC, GaN |

| Wafer Size | 50–300 mmφ (2–12 inch wafer) |

| Bond Pad Metal | Al, AlSi, AlCu, AlSiCu, Cu, Au |

| UBM | E-less Ni/Au, E-less Ni/Pd/Au (Pb and Cyanide-free plating sln.) |

| Material | Ni (5%–10%)P |

| Ni Thickness | 1–5 μm |

| Pd Thickness | 0.05–0.2 µm |

| Au Thickness | Ni/Au:0.05~0.2 µm Ni/Pd/Au:0.02~0.1 µm |

| Thickness Uniformity | ± 10% (8-inch wafer) |

Analytical Tools around E-less Plating Lines

FAQ

Support for wafer sizes of up to 12 inches.

-

It will be possible to handle it.

Support for TAIKO wafers.

-

It will be possible to handle it.

Features of our Electroless UBM Plating Service:

-

Support for various pads and pad sizes with good appearance and stable thickness (Ni/Pd/Au or Ni/Au).

Other products related to High-Functional Materials for Next Generation Devices

- Copper Ink for Fine Lines with Printed Electronics

- High-Purity Metals

- Low α Tin/Bismuth for Soft Error Reduction

- Compound Semiconductor Wafers - InP, CdZnTe -

- Rutile Single Crystals(Furuuchi Chemical)

- Strontium Titanate Single Crystals(Furuuchi Chemical)

- YAG Ceramics for Laser Applications

- Tantalum and Niobium Oxides and Compounds (TANIOBIS)

- AMPERTEC® High-Purity Chlorides(TANIOBIS)

- Photocatalyst for Artificial Photosynthesis

- Sintering Copper Fine Powder