Low α Tin/Bismuth for Soft Error Reduction

Summary

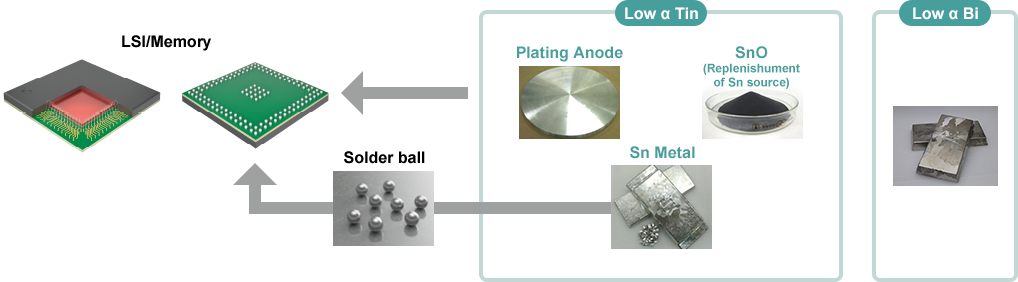

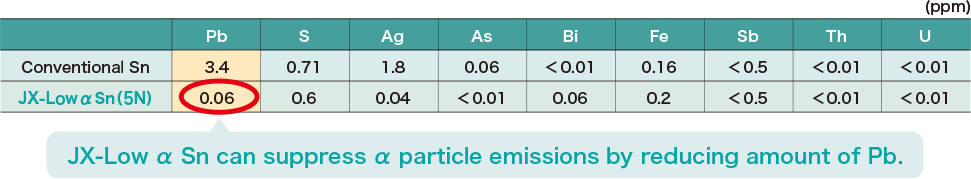

Soft errors are induced by the intrusion of α particles, which can damage an electronic device, more precisely causing memory failure. The problem is getting bigger as device sizes are reduced and solder materials are positioned close to sensitive locations. Our proprietary refining technology reduces impurities in tin—particularly lead, which emits α particles. Utilizing this technology, we develop and manufacture tin with α emission levels that are reliably less than 0.001 cph/cm2. We can process metals in the desired shapes, including ingots or nuggets for anode or melting uses. Tin oxide is also available.

Application Examples

Benefits for Customers

- Our novel purification process enables us to reduce metal impurities, especially alpha radioactive elements.

- Sn purity: 5N (99.999%, α count ≤ 0.002cph/cm2), 6N (99.9999%, α count ≤ 0.001cph/cm2)

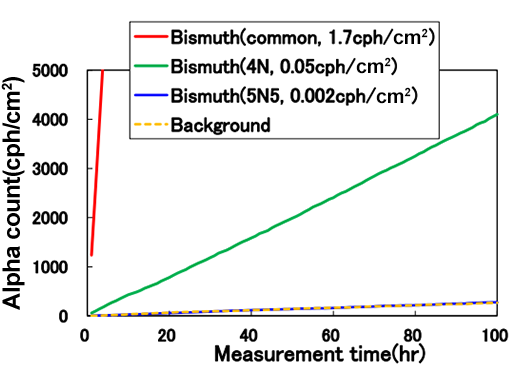

- Bi purity: 4N (99.99%, α count ≤ 0.05cph/cm2), 5N5 (99.9995%, α count ≤ 0.002cph/cm2)

- The alpha radiation dose is stable at a low value and does not change over time.

IC performance and reliability are increased by avoiding the issue of soft error caused by alpha particle emissions.

Features of JX-Low α Tin

- Impurities

Features of JX-Low α Bismuth

Our novel refining process removes Po which is the source of alpha emission and achieve low alpha emission.

FAQ

It is said that low α Sn does not change over time, but how long does it last exactly?

-

We have a track record of measuring up to 16 months after casting.

Regarding low α Sn, what alpha radiation dose do commercial products normally emit?

-

It depends on the product, but it is generally several cph/cm2.

Low α Bi is a development product, but is it possible to obtain a sample?

-

Yes.

Other products related to High-Functional Materials for Next Generation Devices

- High-Purity Metals

- Low α Tin/Bismuth for Soft Error Reduction

- Electroless UBM Formation Service

- Compound Semiconductor Wafers - InP, CdZnTe -

- Rutile Single Crystals(Furuuchi Chemical)

- Strontium Titanate Single Crystals(Furuuchi Chemical)

- YAG Ceramics for Laser Applications

- Tantalum and Niobium Oxides and Compounds (TANIOBIS)

- AMPERTEC® High-Purity Chlorides(TANIOBIS)

- Photocatalyst for Artificial Photosynthesis

- Sintering Copper Fine Powder