Titanium Powder (Toho Technical Service Co., Ltd.)

Summary

Titanium-based and 64-alloy powders (Ti6Al4V) are produced from high-grade sponge titanium and swarf using the hydrogenation dehydrogenation process. By removing fine powder, the oxygen content is reduced, and products are offered that improve the parent density of sintered parts and allow greater freedom in component design.In addition, the stable particle size distribution has earned the company a high reputation among many customers.

Application Examples

Automotive Parts

Aircraft Parts

Medical Equipment

Customer Merits of Titanium Powder of TTS※

※ Toho Technical Service

Ti - Powder

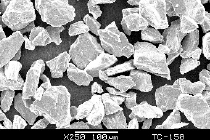

TC-150

High Quality

Coarse Powder

(45~150µm)

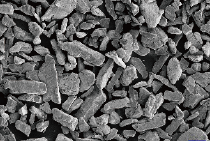

Hydrogenated Powder

TCH150

High Quality

Coarse Powder

(45~150µm)

- High quality Titanium powder made by HDH※ method is supplied at low cost.

※ HDH=Hydride De-Hydride

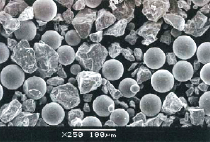

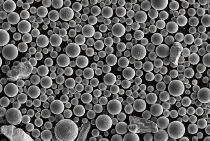

For Additive Manufacturing Powder (Ti-6Al-4V)

ACM150

Ti64 alloy for EBM※

※ Electron Beam Melting

(63~150µm)

ACA+20

Ti64 alloy for SLM※

※ Selective Laser Melting

(20~45µm)

- Ti-6Al-4V alloy powder mixed HDH powder and spherical powder is low cost and has the property of fluidity.

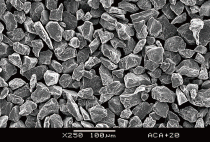

Ti - Alloy Powder※

(Ti-48Al-2Cr-2Nb)※ Under development

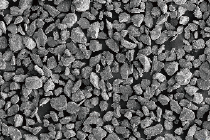

TAB150

Crushed Powder

(45~150µm)

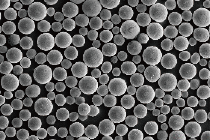

TAB15R

Spheroidized Powder

(45~150µm)

- We can supply the crushed or spheroidized Ti-48Al-2Cr-2Nb alloy powder.

Ti - Alloy Powder※(Ti-5Al-1Fe)※ Under development

AF-150

Crushed Powder

(45~150µm)

AF-15R

Spheroidized Powder

(45~150µm)

- We can supply the crushed or spheroidized Ti-5Al-1Fe alloy powder.

- Ti-5Al-1Fe alloy has the same strength as Ti-6Al-4V alloy.

FAQ

What is your delivery record?

-

We have no mass production experience in 3D modelling.

What is the difference between ACM150 and other companies' products?

-

ACM150 is a cost-effective product by mixing spherical and crushed powder.

Can you provide samples?

-

Yes, samples are available.

What are the main applications?

-

The product is used as a multi-system sputtering target through powder metallurgy.

Can the particle size distribution be adjusted?

-

This depends on the grain size, but particle size distribution can be adjusted by selecting a sieve mesh.