Pure Copper Powder for

Additive Manufacturing

Summary

Due to pure copper’s properties of high electrical conductivity and high thermal conductivity, this powder is expected to be applied to Additive Manufacturing products such as induction coils, heat sinks, and water-cooling units.

In order to expand the applicability of pure copper powder to Additive Manufacturing, we are promoting development aimed at solving various technical issues through surface treatment.

Application Examples

Benefits for Customers

- High-quality pure copper powder with our novel surface treatment.

- Enhanced laser absorption rate improves manufacturability by laser beam method.

- For Electron Beam (EB) AM, the surface treatment exhibits the powder sintering inhibition effect during the preheating process. Such an effect allows us to increase flexibility of AM processing.

- Examples of relative density as manufactured: L-PBF >99% (600 W or higher), DED 98.56%, EBM 99.94%.*

- * Under joint development with Professor Akihiko Chiba, Deformation Processing, Institute for Materials Research, Tohoku University

- The surface treatment adds an anti-oxidization effect and prevents an increase in the oxygen content, which inhibits AM processing.

Improved Absorption Rate

(Laser Beam)

- Example by L-PBF

Laser power:600‐1000W

Relative density:

>99%

Electrical conductivity:

>98%IACS

- Examples by DED

Relative density:89.13%

Electrical conductivity:68%IACS

Relative density:98.56%

Electrical conductivity:100%IACS

Powder Sintering Inhibition Effect

(Electron Beam)

- Images by EBM

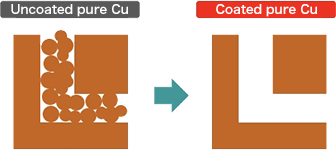

Reduction of partially sintered powders by surface treatment improves powder removal.

※

Through preheating process of electron beam AM, redundant powders can bond with each other excessively by heat, resulting in difficulty in removing the powders.

Specifications of Copper Powder for Additive Manufacturing

| Specification | LB Grade | EB Grade |

|---|---|---|

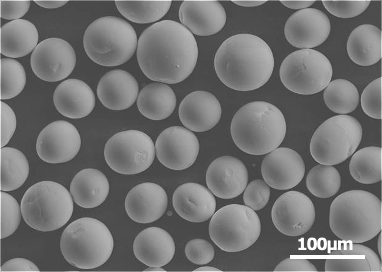

| D50 | 30-45μm | 65-85μm |

| Particle Size | -53μm : >95wt% +53μm :≦5wt% |

-53μm:≦20wt% +53/-106μm:>70wt% +106μm:≦10wt% |

| Purity(Cu) | ≧99.9wt% | |

| Hall Flow | <15s/50g | |