ABD®-900AM New Nickel Powder for Additive Manufacture (Alloyed)

Summary

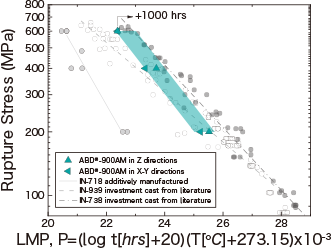

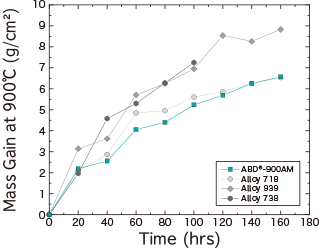

ABD®-900 is a nickel alloy designed using ABD®, an alloy design platform. It is a metal powder for Additive Manufacturing with higher heat resistance and oxidation resistance than IN-939 and IN-738.

Suitable for complex components in the aerospace, electric power, automotive, and space industries.

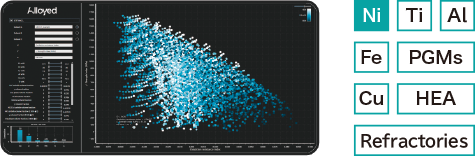

Alloys-By-Design Platform

ABD® platform enables computational alloy design for a wide amount of alloy systems for both conventional and additive manufacturing processes

Ni-alloys for AM: Performance and Applications

- ABD®-900AM was designed using Alloyed’s Alloys-by-design® (ABD®) computational platform.

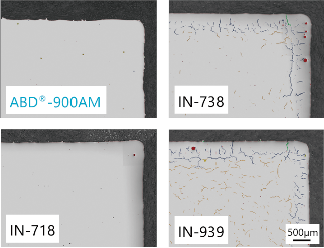

- The alloy allows for crack-free additive manufacture of complex parts, as easily as with IN-718

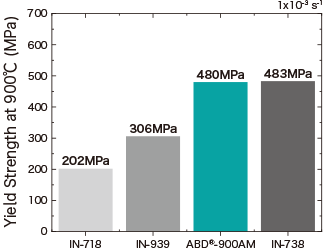

- The new alloy has an increased temperature capability of over 100℃ compared to IN-718, approaching the properties of cast IN-939/IN-738.

Features of ABD®-900AM

Crack-free additive manufacture

Better strength than IN-718 at 900℃

Outstanding creep life due to γ’-phase

Oxidation resistance via Cr2O3 layer

FAQ

Is it possible to develop alloys other than nickel-based alloys?

-

In addition to nickel, we can also design alloys of other metals such as Aluminum and Copper.