AMtrinsic® Powders for Additive Manufacturing (TANIOBIS)

Summary

Based on our high expertise in the development and manufacturing of tantalum and niobium metals and their alloys, we have extended our portfolio by gas-atomized AMtrinsic® spherical tantalum- and niobium-pure metal and alloy powders. This allows to combine unique intrinsic properties of our powders with the freedom of geometric design, offered by commonly available additive manufacturing technologies. Due to our capability to provide customer-specific alloy compositions, powder characteristics can be specifically adjusted to requirements set by different applications.

Application Examples

Tantalum and niobium are characterized by outstanding properties such as high melting points, superior corrosion resistance as well as the highest level of biocompatibility among metals.

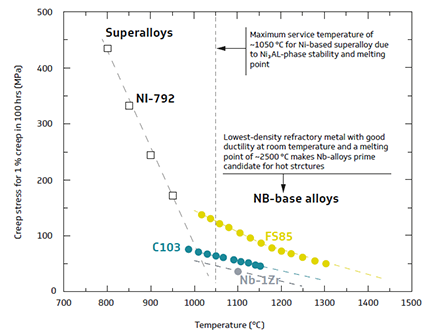

Aerospace

The ultra-high-temperature stability of AMtrinsic® Ta, Nb metal and alloy powders such as Ta-W, FS-85 (Nb-28Ta-10W- 1Zr) and C-103 (Nb-10Hf-1Ti) deliver a perfect fit for aerospace applications.

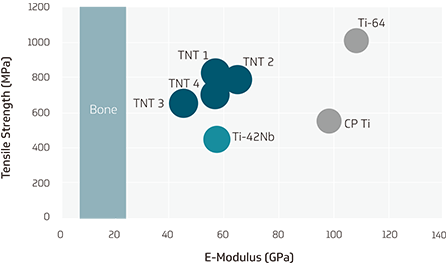

Dental and Orthopedic Implants

The AMtrinsic® biomedical portfolio including pure Ta, Ti-Nb-Ta and Ti-Nb-Ta-Zr, is setting new benchmarks regarding elasticity, strength, ductility and superior biocompatibility for medical implant manufacturing.

Superconductor

AMtrinsic® Nb with its prominent superconducting property finds its application in superconductor industry.

Powder Portfolio

AMtrinsic® spherical powders are pre-conditioned for application in Laser Beam Powder Bed Fusion (L-PBF, 10 – 63 µm), Electron Beam Powder Bed Fusion (E-PBF, 63 – 105 µm), Direct Laser Deposition (DLD, 105 - 150 µm) or in accordance with customer requirements.