Lotus Metal* with High-efficiency Heat Radiation

(Lotus Thermal Solution)

*Metal with porous structure

Summary

Lotus Metal is manufactured by controlling the growth of pores during casting and stretching them in a single direction. Utilizing the characteristics of Lotus Metal enable it to be used as a cooler to solve heat problems in next-generation semiconductors and reduce the cooling cost of servers. It also provides excellent conductivity as a thermal interface material (TIM). We are promoting commercialization aimed at solving heat problems and decarbonization through heat management.

Application Examples

Customer Merits

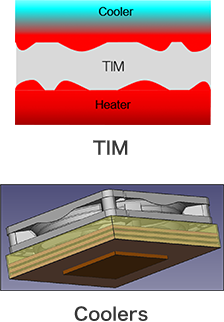

- Using Lotus Metal for TIM materials, coolers, etc. has the following advantages.

Heat conduction equivalent to silver sintering can be achieved with no pressure and low temperature bonding.

Lotus metal & solder bonding

Miniaturization, high performance, and energy saving can be achieved.

Heat flux cooling SiC (SiC with cooling capacity) can be achieved.

Cooler using Lotus Metal

Features of Lotus-type Porous Metal (Lotus Copper)

- Using proprietary technology of Lotus Thermal Solution Inc., we control the structure of holes extending in a single direction like a lotus root, cast porous metal (copper), and develop it for application to heat dissipation materials.

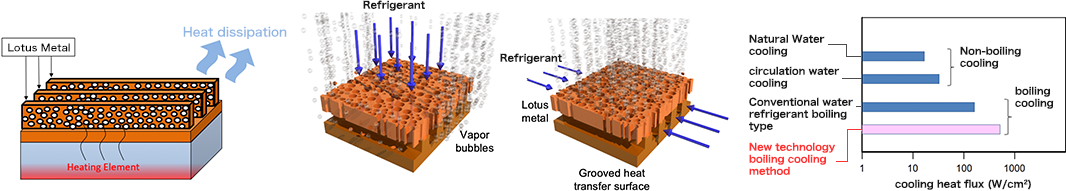

- By using the holes extending in a single direction, it is possible to achieve both the heat transfer properties of copper and the functionality of the porous structure, so the copper can be applied as a heat dissipation material with high heat dissipation efficiency.

- When lotus metal is used in a boiling cooling system that uses vaporization heat, such as water sprinkling, boiling is spontaneously promoted through the exchange of heat (vapor) and refrigerant using the holes, which doubles cooling capacity compared to the conventional water-refrigerant boiling type.

Evaporation cooling using lotus metal (cooling CPU, etc. by vaporization heat)

FAQ

How is Lotus Metal manufactured?

-

During solidification (melting and solidifying the metal), gas is actively melted and manufactured without venting. This is because gas that cannot be completely melted when solidifying, like ice made in a refrigerator, forms pores and remains in the metal. Our strength lies in being able to control the shape, size, and number of pores by adjusting the solidification conditions.

What is the difference between other porous metals and Lotus Metals?

-

In porous metals, which have a sponge-like structure, the pores are arranged in a random manner, but in Lotus Metals, the pores are aligned in a single direction, so they are also called lotus root metals. They offer excellent thermal conductivity and fluid permeability.

Is it possible to obtain samples?

-

We do not provide samples of Lotus Metals and Lotus Fins with free of charge, but it is possible for customers to borrow them with certain conditions (such as time limits).

Please tell us about the workflow for heatsink development.

-

For the prototype, we ask about the usage and usage environment (fan wind, cooling water, etc.), make proposals based on miniaturization and energy-saving thermal design (simulation), and share the effects. We then work on developing a prototype.

Other products related to Thermal Solutions

- Negative Thermal Expansion Material: ZrW2O8

- Via Filling Paste for Thermal Release / Low Specific Resistance and High Reliability Ag Bonding Wire (TATSUTA Electric Wire and Cable Co., Ltd.)

- A New Contact Method by Metal Nanowire (NanoWired GmbH)

- Magnetocaloric Spheres for Hydrogen Liquefaction Magnetic Refrigerator