Electro-Deposited Copper Foil for FPC “JXEFL Series”

Summary

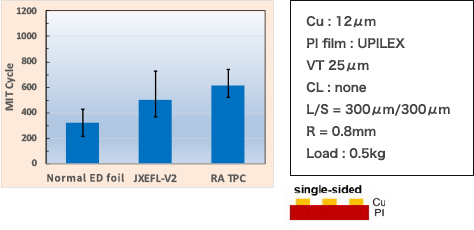

Top-level bending properties achieved by annealing.

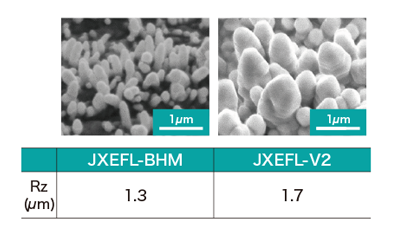

High conductivity and fine nodules give excellent high frequency properties.

Application Examples

Benefits for Customers

- JXEFL has larger grains than normal ED foil, and fewer grain boundaries mean less risk of cracking.

- JX offers both RA and ED copper foils for FPCs and can suggest the best solution for the customer.

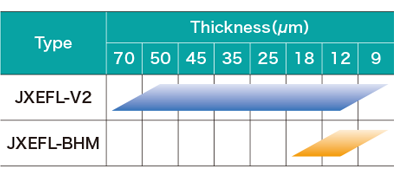

- JX offers various thickness of foil to meet a range of customer requirements.

MIT Test Results

Various thickness lineup

Features of JXEFL

- JXEFL achieves strong peel strength with the base film, despite low roughness.

- BHM surface treatment is suitable for high-frequency applications.

Nodule Side SEM

Transmission Loss

FAQ

What are examples of applications?

-

The JXEFL series has widely been adopted in FPCs for electronic devices. For high-frequency applications, the electro-deposited copper foil has been used in combination with LCP.

What are the differences from competing products?

-

JX offers various thicknesses. The foil offers top-class bendability and better high-frequency performance as electro-deposited copper.

What makes the foil capable of performing its function?

-

Larger grains than normal ED foil and fewer grain boundaries mean less risk of cracking. Fine nodulation on the smooth surface enables high-frequency performance.

Can you provide samples?

-

Yes, we can provide stand-alone samples of copper foil, but please note that it will be used as part of a copper clad laminate in actual usage.