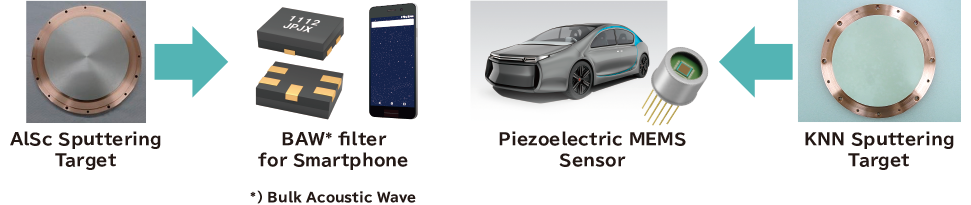

AlSc & K-Na-Nb(KNN) Sputtering Targets for Lead-free Piezo Devices

Application Examples

We are developing AlSc and KNN (K-Na-Nb) targets for Pb-free piezoelectric MEMS to replace PZT (Pb-Zr-Ti).

Benefits for Customers

JX can provide AlSc and KNN Targets for Lead-free Piezoelectric MEMS Sensor.

- Al-Sc-N alloy shows higher piezoelectric coefficient than AlN alloy.

- We developed a manufacturing process to produce AlSc target with low oxygen.

- Maximum φ350mm target size is possible.

Analysis results (not guaranteed spec)

| Sc (Composition A) | Sc (Composition B) | ||

|---|---|---|---|

| Na | <0.1 | <0.1 | ppm |

| K | <0.1 | <0.1 | ppm |

| Fe | 120 | 160 | ppm |

| Co | <1 | 1 | ppm |

| Ni | 30 | 27 | ppm |

| La | 1 | 2 | ppm |

| Ta | <500 | <500 | ppm |

| C | 30 | 30 | ppm |

| O | 490 | 490 | ppm |

| H | <10 | <10 | ppm |

JX succeeded to produce high-Sc AlSc target with low oxygen content.

- KNN provides comparable piezoelectric properties to the PZT system.

- We developed high-density KNN target with high deposition rate.

- Maximum φ300mm target size is possible.

Analysis results (not guaranteed spec)

| KNN | ||

|---|---|---|

| Li | <10 | ppm |

| Al | 200 | ppm |

| Ca | 20 | ppm |

| Mn | <10 | ppm |

| Fe | <10 | ppm |

| Co | <10 | ppm |

| Ni | <10 | ppm |

| Cu | <20 | ppm |

| Zr | <10 | ppm |

| C | 90 | ppm |

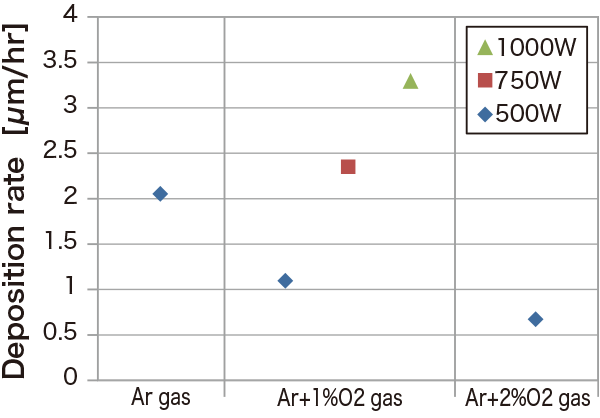

Deposition rate of KNN target

JX achieved high deposition rate (over 3.0µm/hr) for 1kW sputtering power.

Properties of AlSc・KNN

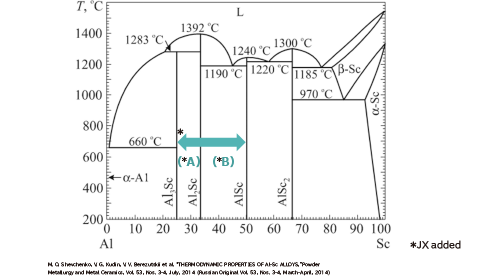

Al-Sc Phase Diagram

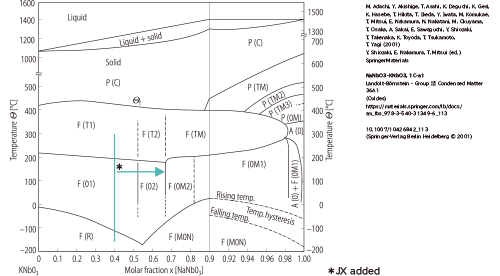

KNbO3-NaNbO3 Phase Diagram