Sputtering Targets for Functional Thin Films

Summary

We have a wide range of sputtering targets for various functional thin films related to "light". Low-resistance/high-transmittance special stacked films are with lower resistance and higher transmittance than ITO films.

IZO films are transparent conductive films with higher transmittance in the near-infrared region than ITO films. No heat treatment is required, allowing sputtering on plastic substrates.

Black films (BM series) can be produced from semi-transparent to fully light-shielding films by adjusting sputtering conditions. Suitable for making dark metallic decorative films, etc., as well as for anti-reflection of metal wiring.

The NS Series offers films with a wide range of refractive indices, allowing optical tuning, high barrier properties, high weather resistance, and other features.

Application Examples

We have a wide range of sputtering targets for various functional thin films related to "light".

It is expected to be used for various light-receiving and light-emitting devices, optical adjustment films, and a variety of other applications.

We can also design materials to meet your requirements.

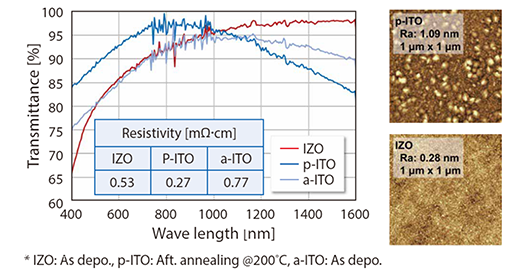

Transparent conductive IZO films in the visible to near-infrared region

Features

This film with higher transmittance in the near-infrared region

than ITO film.

No heat treatment is required, so films can be deposited on resins and other materials.

This with high smoothness due to amorphous film.

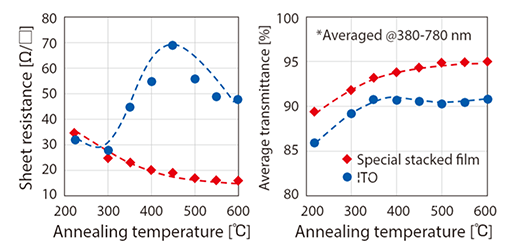

Special stacked film with low resistance and high transmittance

Features

This film has lower resistance and higher transmittance than the ITO film conventionally used as the pixel electrode for FPDs.

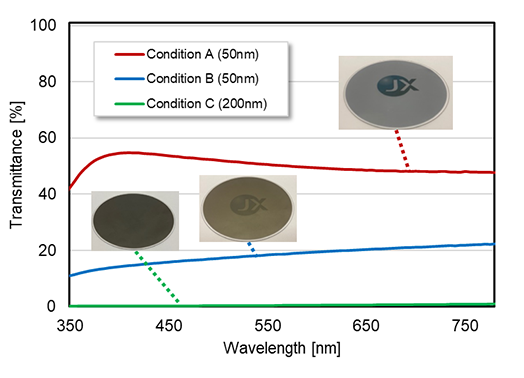

Black film: BM series

Features

Black films (BM series) can be produced from semi-transparent to fully light-shielding films by adjusting sputtering conditions. Suitable for making dark metallic decorative films, etc., as well as for anti-reflection of metal wiring.

Simultaneous etching of stacked films with metal is possible.

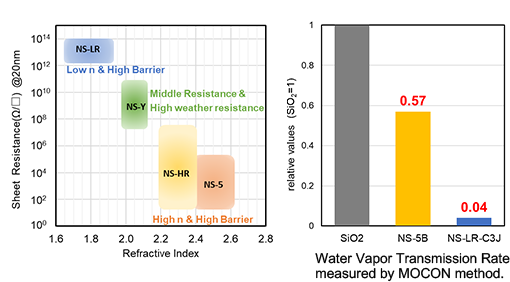

Optical adjustment & high barrier : NS series.

Features

The NS Series offers films with a wide range of refractive indices, allowing optical tuning, high barrier properties, high weather resistance, and other features.

What is sputtering ?

FAQ

What is the deposition method?

-

All materials can be deposited by DC sputtering method. Depending on the material, film properties can be improved or adjusted by introducing a small amount of oxygen into the sputter gas.

Is the special stacked film a characteristic of a single film?

-

Special stacked film is consisting of two layers. By heat-treating at high temperatures, properties exceeding those of ITO can be obtained.

What are the characteristics of IZO film ?

-

IZO is a film with a stable amorphous structure at room temperature, and low resistivity and high transmittance can be obtained in this state; heat treatment for crystallization is not required as with ITO.

Therefore, it is possible to deposit films on resins and other materials that are difficult to heat treat.

It is also resistant to repeated bending and has a small increase in film resistance.

What is the difference between BM membrane and black paint?

-

The BM film can block the reflected light from the metal surface because the surface reflected light of the BM film and the reflected light from the underlying metal surface cancel each other out due to interference effects.

Thus, there is no need for thicker coats as with black paint.

Since the BM film is a thin film, the stacked film with metal can be microfabricated by photolithography and simultaneously etched with the metal film.

How to use NS film ?

-

Light is reflected at the interface between films with different refractive indices, resulting in reduced light transmission. By inserting a film with an intermediate refractive index at this interface, reflection at the interface can be reduced and light transmission can be improved.

The NS series is compatible with a wide range of refractive indices and can be used to improve the transmittance of a variety of stacked films.

The amorphous structure of the film also reduces the film stress generated, making it easy to manufacture stacked films. Since the film itself has barrier properties, it can also function as an encapsulating film.

Regarding the provision of sample membranes for evaluation.

-

Limited substrate size, but can be provided. We can also suggest the optimum material for your usage situation, so please consult with us.