High Strength Rolled Copper Foil for Li-ion Battery

Summary

We have a lineup of high-performance rolled copper foils that have various excellent properties such as high strength and high heat resistance, and we support the development of next-generation high-performance LiBs that use new active materials and manufacturing methods.

Application Examples

Rolled copper foil is used in automotive batteries and mobile devices as a negative electrode current collector.

Benefits for Customers

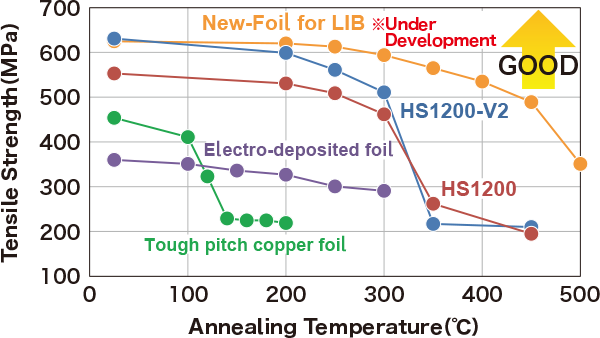

- High strength

- ・Suitable for batteries using Si-based active materials with large volume changes.

- Thin foil (Actual thickness 6µm)

- ・Thin foils are possible due to its high strength, and more current collectors can be stacked with batteries of the same volume, contributing to improved battery energy density.

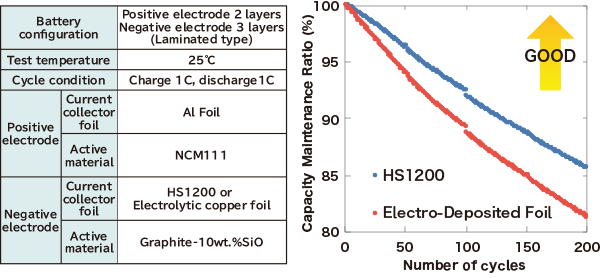

LiB Cycle Test with Different Types of Copper Foils for Negative Electrode Current Collector

Features of High-Strength Copper Foil

- HS1200&HS1200-V2 are high -strength copper alloy foils that have excellent heat resistance in terms of softening.

- New copper alloy foil is being developed with better heat resistance than HS1200.

- When slitting,the maximum width is 670mm and the maximum length is 8,000m.

| Copper Foil | Thickness (µm) | Chemical Composition (wt.%) | Tensile Strength (MPa) |

|---|---|---|---|

| HS1200-V2 | 8~ | Cu-0.12Sn | 630 |

| HS1200 | 6~ | Cu-0.12Sn | 550 |

| Tough Pitch Copper | 6~ | Cu > 99.9 | 450 |

| Electro-deposited foil | - | Cu > 99.9 | 350 |

| New-Foil for LIB ※Under Development | 8~ | Cu-0.1Zr | 620 |

All values are representative, not guaranteed.

Softening Curve (Annealing Time 0.5H)