EMI SHIELDING FILM Line-up Solution for Designing Noise Counter Measures

(TATSUTA Electric Wire and Cable Co., Ltd.)

Summary

In recent years, demand for FPCs used in mobile devices such as smartphones and wearables has been increasing for noise suppression to prevent device malfunctions.

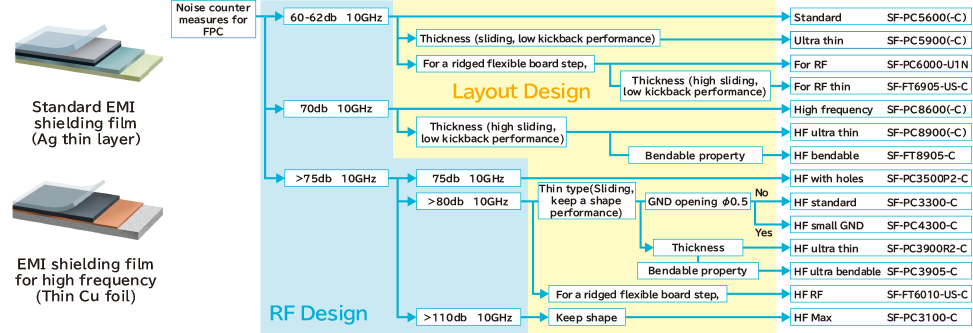

We can solve your design issues with our abundant line of EMI shielding films for FPCs, including copper-foil-type products with high reliability, thin products with a total thickness of 8 μm that contribute to thin designs, special products suitable for dynamic bending, and products for strengthening FPC GND.

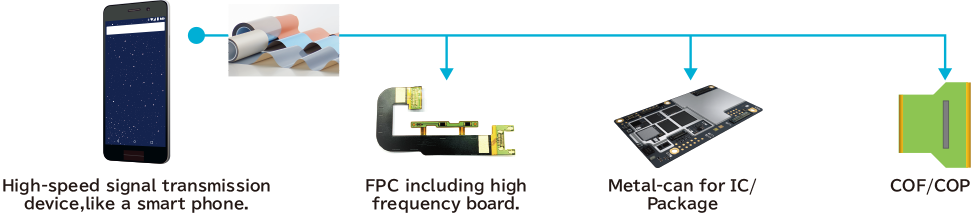

Application Examples

- Many variety of noise counter measures products have been applied a flexible printed circuit board (FPC) being inside of mobile device such as smart phones and a mounted component.

Customer Merits

TATSUTA EMI shielding films have been applying our multi thin layers technology using metallic thin layer, with using our technologies including such as electric properties, layout of board, and process methods can contribute End customers’ challenges to suppress noise so that they can select some as possible solution. Also we have supplementary products to generate design freedom, one of them is Free Grounding Film that is enable a micro wiring board to strengthen GND connection on EMI shielding film +FPC.

- ・SF-PC series・・・・・

Process it on FPC process line because its adhesion is thermal setting type. - ・SF-CA series・・・・・

Use it on many varieties electric devise due to pressure sensitive adhesion as its adhesion layer. - ・FGF series・・・・・

Supplementary material for SF-PC series, enable to take GND connection on EMI shielding film, enhancing design freedom.

- SF-PC series application examples Selection depends on purpose including shield effect and a board layout.

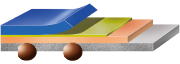

Features of Free Grounding Film

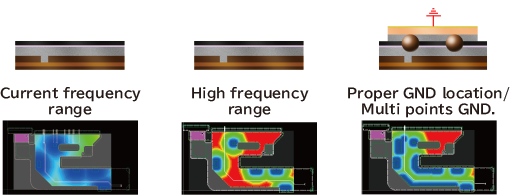

- FGF generate the best Ground connection design on FPC with EMI shielding film.

(Thin Cu layer)

In the current design trend, a high-density wiring or a down sized board applies FGF enables the board multi points GND to leading strengthing shield effect.

FAQ

How does EMI shielding film press to an adherend?

-

This film uses thermosetting adhesives, which require heat, pressure, and time. Suitable for use with any pressing machine commonly used in FPC manufacturing processes.

Can EMI shielding film be purchased directly?

-

Please purchase via FPC manufacturing companies. (Commercial distribution for each company has already been determined.)

What is the core technology of the product?

-

We utilize resin design technology and conductivity technology cultivated through production of electric wires and conductive pastes.

Fine particle dispersion and multi-layered thin film technology are also core technologies.