Surface Treatment Agents for Metals (JX Metals Trading)

Summary

As JX Advanced Metals Group's only development and manufacturing base for surface treatment agents, JX Metals Trading Surface Treatment Division provides comprehensive support for product development, analysis in response to your requests.

As a manufacturer of surface treatment chemicals, we provide plating chemicals for various applications (semiconductors, electronic parts, PWB, decoration).

In addition, through the support system of JX Advanced Metals Group's overseas bases, mainly in Southeast Asia, and cooperation with Japan (Takatsuki Plant), we are able to respond to various requests in a timely manner both in Japan and overseas.

Application Examples

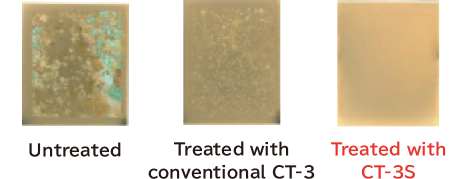

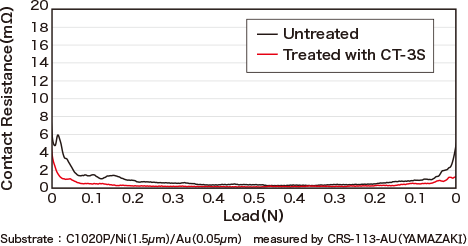

CT-3S Dipping type seal treatment agent for (Ni/)Au

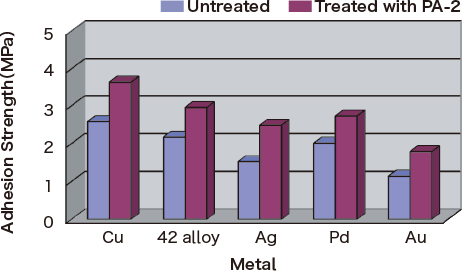

PA-2 Adhesion promoter

Merits of CT-3S to be employed

- To inhibit corrosion of pinholes on Au(Ni)-film and improve reliability of contacts.

- To reduce thickness of Au film and save the cost of Au-plating.

・Salt Spray Test Results: 96h

Substrates:C1020P/Ni (2µm)/Au (0.05µm)

Test Condition:JIS Z 2371

Features of CT-3S

- To achieve excellent corrosion resistance with shorter treatment time compared to conventional CT-3

- Not to influence contact resistance and other properties with its monomolecular coating characteristics.

- To be soluble in water and not to include any organic solvents and heavy metals.

Merits of PA-2 to be employed

- To improver adhesion strength between resin and Cu, Fe-Ni alloy, Ag, Pd, and Au.

・Effect of Adhesion Strength between resin and metals

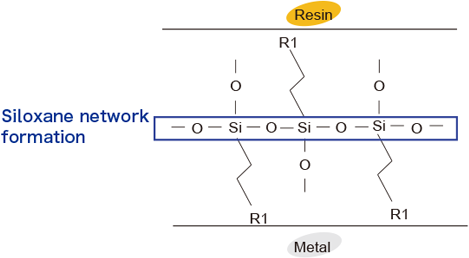

Features of PA-2

- Our uniquely developed silane-coupling agent to uniformly absorbs onto metal surfaces.

- The functional group of the Our silane-coupling agent to accelerate hardening of resin.

- To provide copper and copper alloys with corrosion resistance.

FAQ

What are the selling points of CT-3S?

-

Continuously wet-treating the plated product gives the plating film a corrosion-resistant effect.

It is a water-soluble surface treatment chemical.

How do I use CT-3S?

-

This product is diluted at the specified dilution ratio and immersed at the specified temperature and pH. After treatment, it is washed with water and dried.

How is CT-3S different from other products and conventional products?

-

Three points of appeal for CT-3S:

- ①Improved corrosion resistance: processing can be performed in a shorter time than conventional products, and corrosion resistance is improved (salt spray, nitric acid aeration, etc.).

- ②Monomolecular adsorption film: keeps contact resistance value low and does not affect soldering characteristics.

- ③Water-based sealing agent: treatment of effluent is easy because it does not contain organic solvents that cause environmental pollution. No need for explosion-proof equipment leads to safe working environments.

What is the introduction record of CT-3S?

-

It is a development product.

What kind of product is PA-2?

-

PA-2 is a water-soluble surface treatment chemical that improves the adhesion between precious metal surfaces and epoxy resin by continuously (R to R) wet-treating precious metal-plated items.

How is PA-2 different from other products and conventional products?

-

Three points of appeal for PA-2:

- ①Originally-developed silane coupling agent: adhesion improver between resin (epoxy) and precious metal.

- ②Monomolecular adsorption film: does not affect assembly characteristics of solder or interfere with the original characteristics of metal.

- ③Water-based sealing agent: no need for explosion-proof equipment leads to safe working environments.

What is the introduction record and market share of PA-2?

-

It is used by LF manufacturers. Chinese LF manufacturers have performed final surface treatment, and it has demonstrated effectiveness in improving adhesion with sealing resin after assembly.

How is PA-2 used?

-

This product is diluted at the specified dilution ratio and immersed at the specified temperature and pH. After treatment, it is washed with water and dried.